Raw Water Sources

The water treatment process begins with raw water from Allatoona Lake being pumped from the intake six miles to our Wyckoff Water Treatment Plant in Acworth. At the intake, gates are used to change the elevation intake point based on lake quality and lake level issues. Pre-treatment chemicals like Powdered Activated Carbon may be added at the intake to treat for seasonal increases in non-harmful organic constituents which can create taste and odor issues in drinking water. Sodium Hypochlorite can be added periodically to clean raw water lines by removing any organic growth within the line.

Launch 360 ViewPre-Treatment

The pretreatment process aims to improve the quality of the raw water prior to the main treatment process. Pre-treatment chemicals seek to reduce the natural variations or extremes in water quality. Pre-treatment chemicals prepare the water for the main treatment process by changing the form of the hard to remove naturally occurring contaminants into easier to remove compounds. Chlorine Dioxide is added to aid removal of naturally occurring iron and manganese, which can color the water and stain fixtures like toilets.

Chemical coagulants like aluminum sulfate (or alum) are added to react with small clay and organic particles in the water to form larger particles heavy enough to settle out (“floc”). The alum has a charge opposite of the organic particles. When added to the water, it neutralizes the negative charge of the organic particles which allows them to stick together. After pre-treatment chemicals are added, the water flows into a splitter box which divides the water between sedimentation basins.

Launch 360 ViewFlocculation

The water flows through chambers containing baffling boards to gently mix the water, allowing floc particles to grow large and heavy enough to settle out in the next process. Flocculation increases the floc particle size, continuously building with additional collisions and interaction with the added alum. Once the floc has reached its optimum size, the water is ready for sedimentation.

Launch 360 ViewSedimentation

The floc settles by gravity to the bottom of a sedimentation basin. Clean water travels up through the plate settlers and spills over into the weirs. and the clarified water then flows to the filters. On its way, hypochlorite is added to it to start the disinfection process. Sediment from the basins is collected and treated to create a beneficial soil amendment to be used on farms.

Launch 360 ViewResiduals Management

CCMWA collects and treats the solids removed through the sedimentation process and manages a program to spread the treated residuals on nearby farmland to restore the pH in the soil to an ideal agricultural level. Water removed during the residuals treatment is recycled through the plant.

Launch 360 ViewFiltration

Filtration helps to remove remaining particles from the water after the sedimentation step. The force of gravity moves the water through filter media, composed of sand and anthracite coal. As water moves through the filters and the pipe gallery, automated valves regulate flow through the filters, while online instruments continuously measure water quality. Typically, after 150 hours, each filter is backwashed to remove particles that have accumulated in the media.

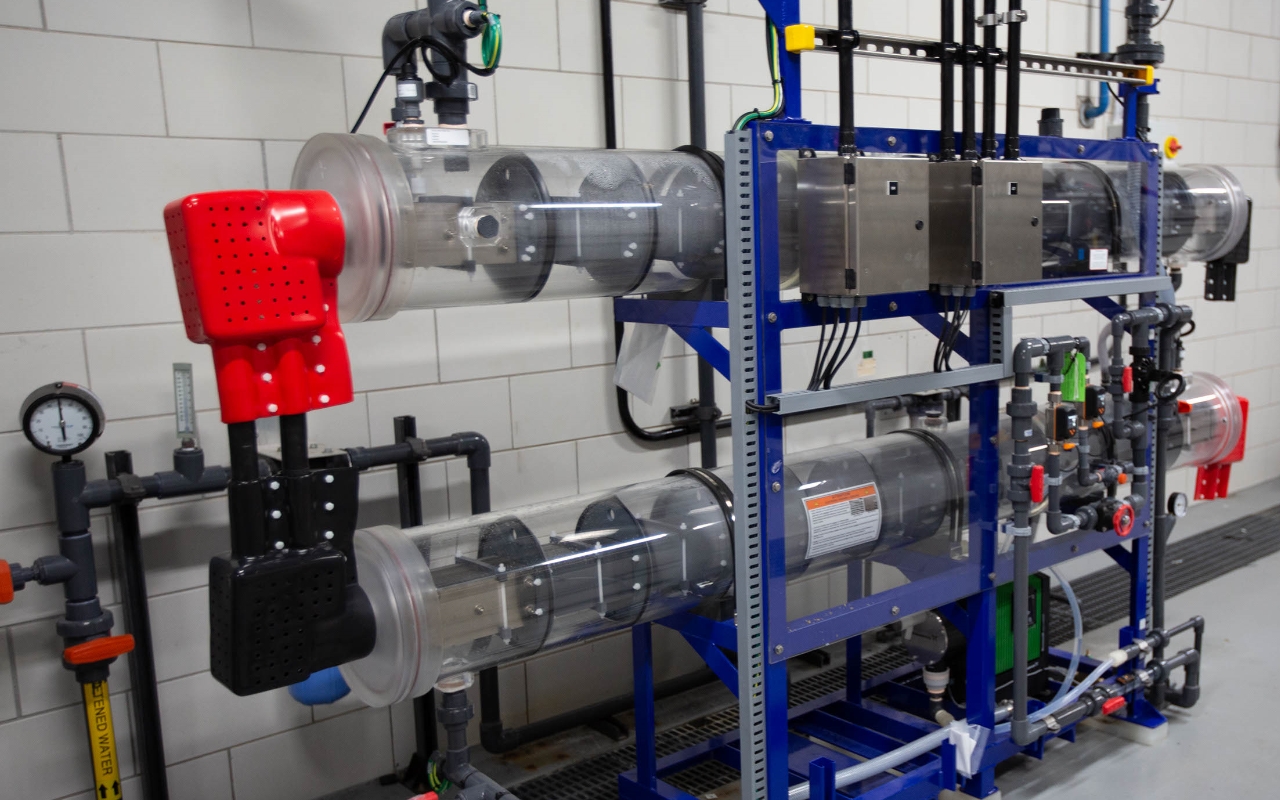

Launch 360 ViewGranular Activated Carbon

During the warmer months of the year, ( typically Spring through Fall) a percentage of our filtered water receives an additional treatment step by flowing through Granular Activated Carbon (GAC) contactors which absorb microscopic natural organic compounds that can combine with the chlorine disinfectant to produce regulated disinfection byproducts. The Wyckoff GAC facility is the largest GAC facility in the southeast with a total of 28 GAC contactors capable of treating 36 million gallons per day (MGD).

Launch 360 ViewPost Chemical Treatment

The final treatment step is the addition of post treatment chemicals to the filtered water. Sodium hypochlorite is added for disinfection and ensures a residual disinfectant is available to prevent bacteria growth in the distribution system. Calcium hydroxide (lime) is added to adjust the pH of the water to improve the taste and to provide protection from corrosion of lead and copper in home plumbing systems. Lastly, fluoride is added for prevention of tooth decay.

Launch 360 ViewClear Wells

Once treatment is complete, the water travels through the clear wells for a time sufficient to allow the post treatment chemicals to properly interact with the water to ensure complete disinfection and stabilization prior to pumping into the system.

Launch 360 ViewHigh Service Pumps

High service pumps push water into CCMWA's transmission piping system, which carries the water to our wholesale customers' distribution systems. Water is pumped at a pressure and flow sufficient to ensure all system demands are met, including fire protection needs.

Launch 360 ViewDistribution

The water treatment process begins with raw water from Allatoona Lake being pumped from the intake six miles to our Wyckoff Water Treatment Plant in Acworth. At the intake, gates are used to change the elevation intake point based on lake quality and lake level issues. Pre-treatment chemicals like Powdered Activated Carbon may be added at the intake to treat for seasonal increases in non-harmful organic constituents which can create taste and odor issues in drinking water. Sodium Hypochlorite can be added periodically to clean raw water lines by removing any organic growth within the line.